CX SERIES

Content

USE

- - Foundation work

- - mixed work

- - stone carving work

- - the substrate processing operations

- - casting cutting operations

- - grinding operations

- - Drilling

- - metalworking operations

- - artillery operations

- - inlet air transport and crushing operations

- - mixer operation

- - Cutting process (flame occurs operations)

- - the powder injection operations

- - grinding operations

- - wood processing job.

FEATURES

| MANOMETER | Accumulation of dust filter is easy to assess the situation, can easily know when to replace the filter. |

|---|---|

| FILTER | - In the form of a filter cartridge structure to improve the filtration area , fine dust can be collected even - You have a filter unit with a simple structure is easy to replace |

| Continuos Operating | Dust collector automatically eliminated during operation because 24hours continuous operation is possible. |

| Control Panel | Built-in centralized power switch and differential pressure for the adoption and improved visibility by intensive, Lenticular damage or failure rate is low. |

| TURBO BLOWER | - Balancing work with high-precision press molds and electronic vibration and noise realization, increase in intake efficiency, minimize air friction. - Decomposed and simplified maintenance and repair easy to assemble. |

| FILTER CLEANING | Air Pulse Type (Valve and Tank that has a built-in) attached to the cartridge filter dust Pulse Timer automatically by operation of compressed. air Blow Tube pull air through the spray spread around the elimination efficiency is high because even microscopic dust particles. |

| Painting | - Exclusive Design and color - Very strong to heat and endurance |

SPECIFICATION

| Model | Output (kw) |

Airflow (cmm) |

Pressure (mmaq) |

Filter | Size (㎜) |

Dust Drawer (ℓ) | Weight (㎏) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size (w×l) |

Qty | Area (㎡) |

a | b | c | ød | e | øg | h | ||||||

| CX-101 | 0.75 | 12 | 230 | Ø200×500L | 3 | 8.1 | 700 | 630 | 1,450 | 125 | 300 | 150 | 90 | 16 | 180 |

| CX-202 | 1.5 | 25 | 4 | 10.8 | 750 | 680 | 1,520 | 150 | 325 | 200 | 90 | 45 | 220 | ||

| CX-303 | 2.2 | 40 | 7 | 18.9 | 850 | 750 | 1,570 | 200 | 360 | 250 | 90 | 65 | 250 | ||

| CX-404 | 3.7 | 50 | 8 | 21.6 | 850 | 780 | 1,620 | 250 | 375 | 300 | 90 | 70 | 300 | ||

| CX-505 | 3.7 | 60 | 9 | 24.3 | 850 | 750 | 1,587 | 250 | 375 | 300 | 90 | 80 | 380 | ||

| CX-707 | 5.5 | 80 | Ø200×1000L | 0 | 48.6 | 950 | 900 | 2,190 | 300 | 435 | 350 | 90 | 100 | 490 | |

| CX-1010 | 7.5 | 100 | 12 | 64.8 | 1,370 | 1,030 | 2,440 | 350 | 500 | 400 | 100 | 130 | 580 | ||

| CX-1500 | 5.5×2 | 150 | 16 | 86.4 | 1,670 | 1,050 | 2,440 | 400 | 510 | 450 | 100 | 130 | 720 | ||

| CX-2000 | 7.5×2 | 200 | 20 | 108 | 1,900 | 1,050 | 2,440 | 450 | 510 | 500 | 100 | 170 | 940 | ||

| CX-2000 | 11×2 | 300 | 24 | 129.6 | 2,150 | 1,050 | 2,440 | 500 | 510 | 550 | 100 | 170 | 1,450 | ||

※ This specification shall be changeable without notice in order to improve capability.

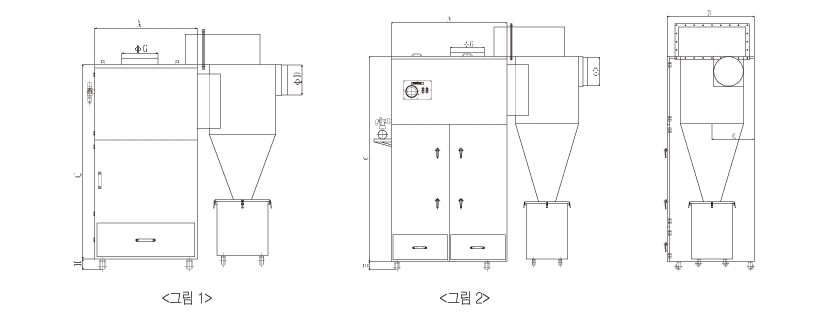

STANDARD DIMENSION